SH-300

HOME > SH-300

HOME > SH-300

-

045 Edge Banding Machine SH-300

- This machine automatically applies and finishes edges to workpieces.

- It is designed to perform edge banding work for 0.45 mm edges.

- The process specifications can be customized to meet customer requirements.

-

Process/Unit/Features

-

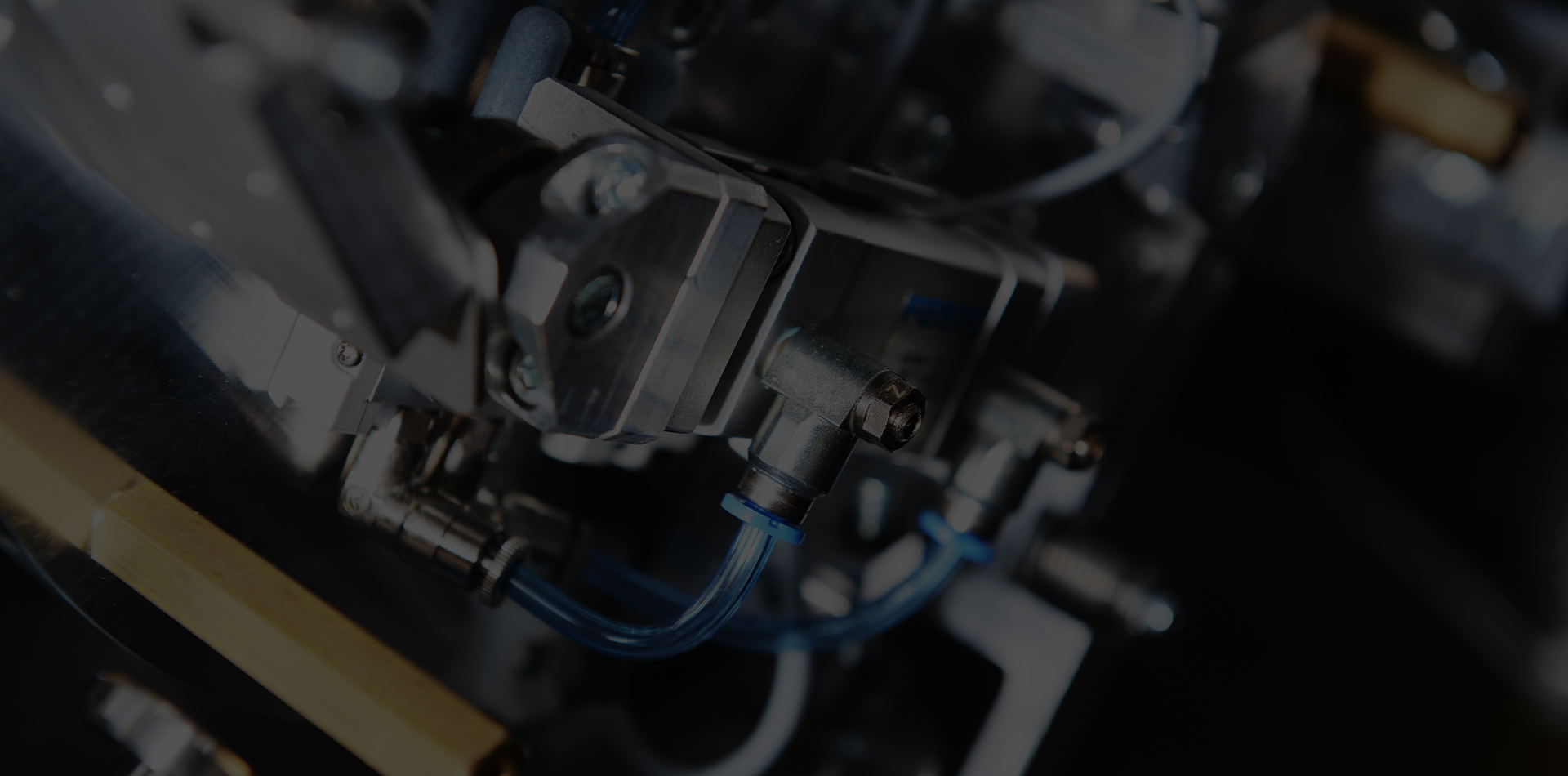

Gluing

Gluing the edge and pressing it using rollers.

Since the drive motor of the glue container and the gluing roller are integrated, it is possible to apply uniform glue with minimum pressure.

-

First end cutting

Cut the front side of the hanging edge to match the length of the workpiece.

Blade cutting minimizes edge damage by supporting the edge while it is cut.

-

0.45 Trimming

Trimming the top and bottom 0.45mm edge overhang.

A 0.5R cutter is used to trim smoothly. Edge remnant can be blown away using air.

-

Second end cutting

Cut the end side of hanging edge to match the length of the workpiece.

Blade cutting minimizes edge damage by supporting the edge while it is cut.

-

Buffing

Wipe off the glue residue on the top and bottom of the workpiece.

A rotating buffing cloth wipes away bond residue from the product surface.

-

-

Machine operation clip

※ Joint Trimming, motor trimming, scraping, and grooving are not applicable. -

Basic model specification

Model SH-300 Size(L*W*H) 4250 * 1000 * 1400 Feeding speed 16m/min(Option 24m/min) Electric 220/380V 10KW Air pressure Above 6kgf/cm2 Supportable Edge 0.45mm Soft Workpiece Thickness 9~50mm(Option 80mm) Feeding Interval 100mm Min. workpiece width 50mm Control Method Limit Sensor ※ Custom manufacturing (changes to the process specifications) is possible for each model according to customer requirements.